Member 1 RC column Design Report Page 1 of 13 REFERENCES CALCULATIONS RESULTS Code: ACI 318-14 MEMBER #1 (SECTION POSITION 192.0 INCHES) COLUMN DESIGN. ACI 318 - 89, 99, Gergely-Lutz equation ACI requirements based on stress limits derived from the Gergely-Lutz equation: Code provisions for crack widths x)-x)/(d-(h 3 Adfz cs unitsmNzw 12 max 1011 Samirsinh P Parmar, Asst.Prof. DDU, Nadiad, Gujarat, India 15.

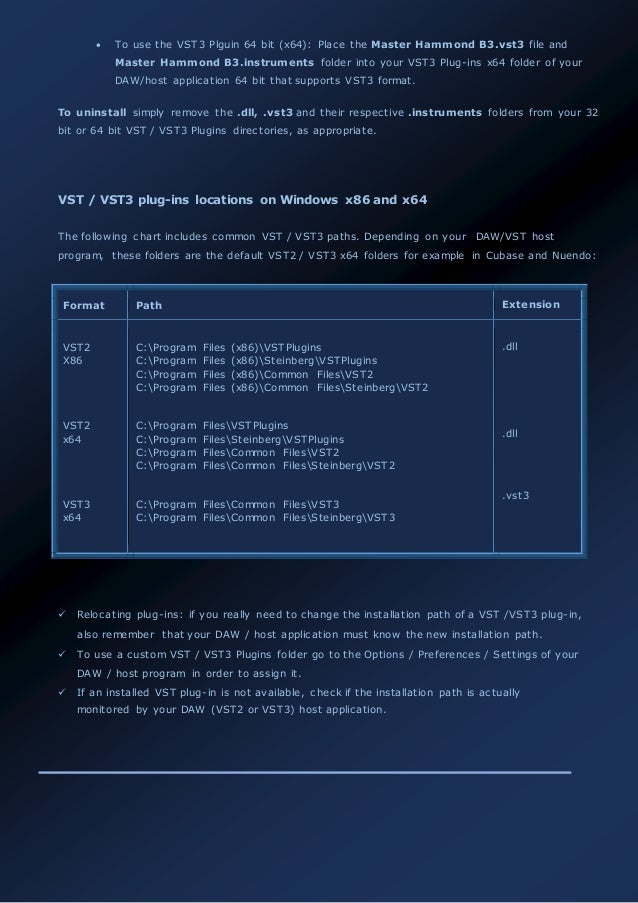

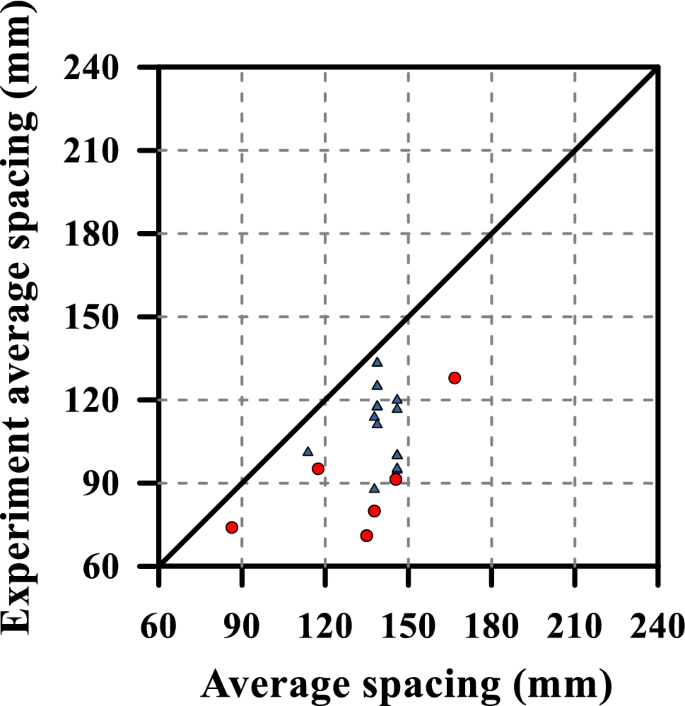

Crack spacing, crack width and tension stiffening effect in reinforced concrete beams and one-way slabs vii results are used to select the set of parameters that has the most significant effect. If the reinforcement spacing is set equal to the limiting values of Eqs. And in ACI 318-05, then the maximum flexural crack width can be controlled within the range from 0.40 to 0.50 mm. ACI 318-14 also uses the design equations that were recommended by ACI 318-05 for flexural crack width control. A: The ACI 318-14 Commentary to Section 6.6.3.1.1 states: 'If the factored moments and shears from an analysis based on the moment of inertia of a wall, taken equal to 0.70Ig, indicate that the wall will crack in flexure, based on the modulus of rupture, the analysis should be repeated with I = 0.35Ig in those stories where cracking is.

FOR WATER TIGHT STRUCTURES

Crack width is a complex and tough topic. Most people still use 20 years old method defined in ACI 318-95. The situation becomes more complex if axial tension force and moment is combined to calculate crack width. One of the examples is large water tanks above ground. This tutorial aims at explaining details and methods in different ACI documents. Latest method defined in ACI 350-06 should be used. Given the variability and non-linear behaviour in long-term deflection and crack widths, it is NOT NEEDED to go for detailed sophisticated calculations for these effects. You can imagine this as calculating something non-linear (crack widths or long-term deflection) from linear-elastic analysis. You have to have some approximations for that. No matter how detailed are your calculations, you still can't predict for certain the long-term deflection and crack widths.

Three ACI documents for crack width; ACI 224R-01, ACI 350-01 & ACI 350-06

1. ACI 224R-01

Some notes:-

- Table 4.1 is based on Nawy findings.

- The table is just a general guide line.

- The table gives w=0.004″ or 0.10mm for water retaining structures.

- It is expected that portion of cracks will exceed these values by a significant amount.

- No relationship between level of cracking & corrosion in long-term.

- More cover can be used even if it yields larger crack width, against corrosion.

- ACI methods deal only with conventional concrete for crack width.

- Crack width is directly proportional to dia of bar & fs and inversely to area of steel.

- Three reasons for limiting crack widths

1-Appearance

2-Corrosion

3-Water tightness

There are three methods mentioned in this document

A) ACI 318-95

Statistical method of Gergely & Lutz 1968

Covers up to 2.5″ only

z in any units

For two-way slabs see section 4.3 of ACI 224R-01

For shallow beams/thick one-way slabs: (w in inches)

Thick means L/D = 15-20

d used here will be distance to the center of bottom bar nearest to tension face.

Film serial turcesc havin doua vieti o dragoste. ß=1.25 to 1.35 if cc≥1″

ACI 318-95 section 10.6 says use ß=1.20 & fs=0.6fy

ACI 340R has design aids for z

ACI 318-98 & earlier max z=175 kip/in for interior exposure based on 0.41mm probable crack width(0.016″)

ACI 318 max z=145 kip/in for exterior exposure based on 0.33mm probable crack width(0.013″)

B) ACI 318-99

No distinction for interior/exterior exposure

For beams & one-way slabs:

fs=0.6fy

Not for aggressive/water tight structures

C) EUROPEAN CODES

—————————————————————————————————————————

2. ACI 350-01

Crack Width Calculation As Per Aci 318 14 Pdf

Same concept like ACI 224R-01

—————————————————————————————————————————

3. ACI 350-06

2 types of exposure:-

i)Normal

ii)Severe

can be taken = 25

where c is at service load

ß can be taken = 1.20 for h≥16″

Thick means L/D = 15-20

d used here will be distance to the center of bottom bar nearest to tension face.

Film serial turcesc havin doua vieti o dragoste. ß=1.25 to 1.35 if cc≥1″

ACI 318-95 section 10.6 says use ß=1.20 & fs=0.6fy

ACI 340R has design aids for z

ACI 318-98 & earlier max z=175 kip/in for interior exposure based on 0.41mm probable crack width(0.016″)

ACI 318 max z=145 kip/in for exterior exposure based on 0.33mm probable crack width(0.013″)

B) ACI 318-99

No distinction for interior/exterior exposure

For beams & one-way slabs:

fs=0.6fy

Not for aggressive/water tight structures

C) EUROPEAN CODES

—————————————————————————————————————————

2. ACI 350-01

Crack Width Calculation As Per Aci 318 14 Pdf

Same concept like ACI 224R-01

—————————————————————————————————————————

3. ACI 350-06

2 types of exposure:-

i)Normal

ii)Severe

can be taken = 25

where c is at service load

ß can be taken = 1.20 for h≥16″

& 1.35 for h<16″

where appearance is of concern & cover exceeds 3″, also check equation 10-7

Exposure defined as

Previous codes (ACI 350-01) puts following limits on z:

Normal exposure: z=115 kip/in (w=0.010″ or 0.254mm)

Severe exposure: z= 95 kip/in (w=0.009″ or 0.229mm) Fanuc 21i t manual.

—————————————————————————————————————————

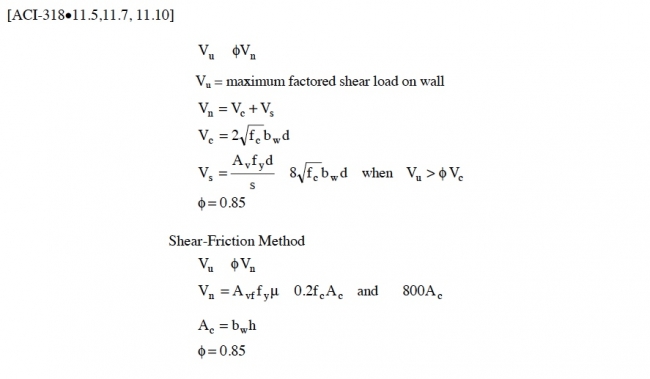

EXAMPLE WITH AXIAL TENSILE LOAD AND MOMENT

- For detailed calculations, find the N.A. depth but use ԑ at service loads. Strain diagram will be different from the one shown in figure above if axial load is included.

- Assume no strength from concrete due to axial tension load.

- Assume tension force acting at steel reinforcement level.

- Assume all the moment is resisted by top and bottom steel only.

- Tension at top steel; T1 = A's / (A's+As+As1+As1) x Total Tension Force

- Tension at bottom steel;T2 = As / (A's+As+As1+As1) x Total Tension Force

- Tension at right steel; T3 = As1/ (A's+As+As1+As1) x Total Tension Force

- Tension at left steel; T4 = As1/ (A's+As+As1+As1 )x Total Tension Force

- Taking moment about top steel:

M=Asfs(d-d')+T2(d-d')+0.5T3(h/4)+0.5T4(h/4)

T3=T4 so

M=Asfs(d-d')+T2(d-d')+T3(h/4)

Crack Width Calculation As Per Aci 318 14 Free

(where T is total axial tension force)

From here calculate fs and compare with fsmax of ACI 350-06.